Klimax DS torque recommendations

Moderator: Staff

Re: Klimax DS torque recommendations

This one is on the US ebay site. It's not hundreds, but is over one hundred :)

http://www.ebay.co.uk/itm/Sturtevant-Ri ... 256aec14ff

You might get one cheaper if you keep a regular eye out. I also bought mine second hand from the US via ebay. Always a risk involved buying second hand, although this seller does offer a 30 days return policy.

http://www.ebay.co.uk/itm/Sturtevant-Ri ... 256aec14ff

You might get one cheaper if you keep a regular eye out. I also bought mine second hand from the US via ebay. Always a risk involved buying second hand, although this seller does offer a 30 days return policy.

Re: Klimax DS torque recommendations

Thanks Charlie1 - gives me something to aim at and keep looking around.

don

don

- rowlandhills

- Very active member

- Posts: 582

- Joined: 2008-01-27 19:25

- Location: York, UK

Re: Klimax DS torque recommendations

Strikes me as the kind of tool which is essential when needed but infrequently used...

Maybe you could share with another local user, or persuade your dealer to get one and loan it to good customers?

Maybe you could share with another local user, or persuade your dealer to get one and loan it to good customers?

KRDSM, Tundra to 242s

Silvers, K400, Hutter rack

Silvers, K400, Hutter rack

- rowlandhills

- Very active member

- Posts: 582

- Joined: 2008-01-27 19:25

- Location: York, UK

Re: Klimax DS torque recommendations

On a different note - I'd also love to see any recommendations for KRDS/0 and KRDS/1 torques.

KRDSM, Tundra to 242s

Silvers, K400, Hutter rack

Silvers, K400, Hutter rack

Re: Klimax DS torque recommendations

They come up used on eBay in the US all the time and generally go $40 or $50. There are also places in the US that sell them new for somewhere between $150 and $180 - you might try a Google search. I know Fredrik just bought a new one recently so maybe he will pop on here and recommend the vendor.donuk wrote:As a brief aside, if the OP does not mind:

Where in the UK can one buy a suitable torque wrench that does not cost hundreds of pounds?

donuk overcast downtown York

The LP12 Whisperer

Manufacturer, Distributor, Retailer and above all lover of music.

Manufacturer, Distributor, Retailer and above all lover of music.

Re: Re:

Erik wrote:I say no. A couple of years ago when I upgraded the KDS/O to /1 I tired out the torque for the board on the Renew and surprisingly found it best around 0.6Nm. I can't recall the exact value as I sold it short after receiving it.fieldmice wrote:Hello Rufus and All,

Just wonder if I can use the KDS torque setting on my KRDS/0 ?

As per Rufus's setting:

KDS boards 0.9Nm, earth bolt 2.9Nm

Thanks and have a nice day.

Kam..

/Erik

Right on the money Erik. I just set the torques on a KRDS/1 and found .6Nm +2 notches was definitely most musical for the main board. I tried settings around the.4Nm mark and a few around 1.0 where I liked 1.0 -1 notch. But then trying settings near .6 it became quickly obvious that .6 +2 was more natural and expressive than the higher torque. The back plate screws I like at .8Nm -2 notches. The ground was very tight already but setting it to 3.4Nm -3 notches did improve things. I did not try other torques on the ground as you have to completely disassemble the unit, removing the main board completely, in order to get the cover off the power supply. The power supply itself floats so the only other torques are the power supply cover and top cover which are best at .6Nm - 4 notches. The usual note applies in terms of having to listen for yourself as torque drivers vary a bit. My .6Nm - 4 notches is .6Nm -3 notches on Fredrik's driver and the torque Paolo found for the grounds (works on Klimax gear, Sagatuns and Tundras and now on KRDS) is 3.4Nm -2 notches but that ends up being 3.4Nm -3 notches on Fredrik and my drivers.rowlandhills wrote:On a different note - I'd also love to see any recommendations for KRDS/0 and KRDS/1 torques.

I don't know for sure yet if the same main board torque works for the KRDS/0 although the other torques would all be the same. I expect it is likely to be the same too but I note that Linn changed the screws from the /0 to the /1. The original version has Posidriv screws but the /1 I just worked on uses Torx so this could have an effect on the torque. I will know for sure relatively soon as I have a KRDS/0 at home which I will be taking apart soon. I had actually torqued this before I owned it (except for the ground due to the hassle of getting to it) but I lost my notes and can't remember the MB settings. But since hearing the that the precise ground setting does make an improvement here I will be forced to disassemble the whole thing so I can get at it. Note that doing this is not for the faint of heart as you either need to have a special tool to get the RCAs off or you have to be really good with a set of very pointy needle nose pliers (I have the special tool). You also need to have a T6 tip for the tiny screws that hold in the XLR connectors and be very careful with them. I have a torque setting for them of .4Nm -2 but can't always use it. These screws have coarse threads that go into plastic. Because of this it is not unusual to find them stripped from the factory. Indeed on the KRDS/1 I just did I was only able to tighten one of the four screws properly for this reason. Due to the rebuild I expect stripped XLR screws are even more likely on RDS units than on original DS pieces. I will post an update when I have verified the MB torques for the KRDS/0.

The LP12 Whisperer

Manufacturer, Distributor, Retailer and above all lover of music.

Manufacturer, Distributor, Retailer and above all lover of music.

- rowlandhills

- Very active member

- Posts: 582

- Joined: 2008-01-27 19:25

- Location: York, UK

Re: Klimax DS torque recommendations

Thanks Thomas. Sounds like I need to invest in a torque driver and spend an hour or two sorting things out...

KRDSM, Tundra to 242s

Silvers, K400, Hutter rack

Silvers, K400, Hutter rack

-

kallesprätt

- Active member

- Posts: 108

- Joined: 2014-05-17 08:06

Re: Klimax DS torque recommendations

Thanks Thomas!

It made a nice improvment, I also found out that my torquedriver at these torques is -2 notches from yours.

Thank again.

/kallesprätt

It made a nice improvment, I also found out that my torquedriver at these torques is -2 notches from yours.

Thank again.

/kallesprätt

Re: Klimax DS torque recommendations

Glad to hear it worked for you. Last weekend I went over my KRDS/0 and found that despite the posidriv screws the .6-2 setting was the best here as well. I also took it all apart and did the 3.4-3 setting for the ground. I've never heard my unit this musically enjoyable. Lorena McKennit's "The Visit" was stunning.kallesprätt wrote:Thanks Thomas!

It made a nice improvment, I also found out that my torquedriver at these torques is -2 notches from yours.

Thank again.

/kallesprätt

The LP12 Whisperer

Manufacturer, Distributor, Retailer and above all lover of music.

Manufacturer, Distributor, Retailer and above all lover of music.

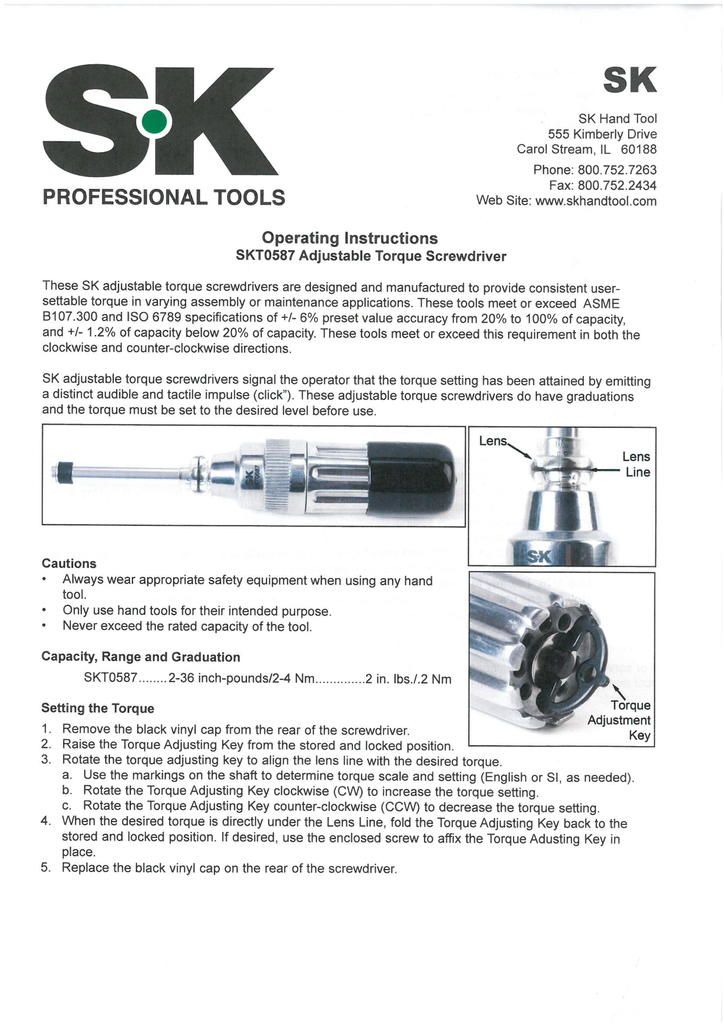

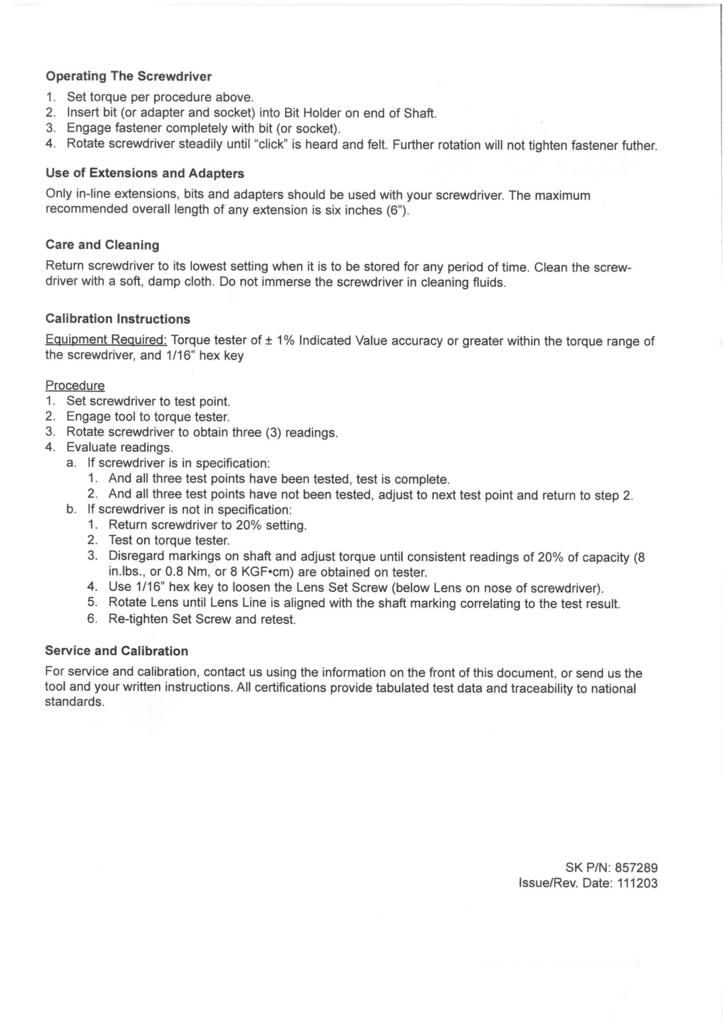

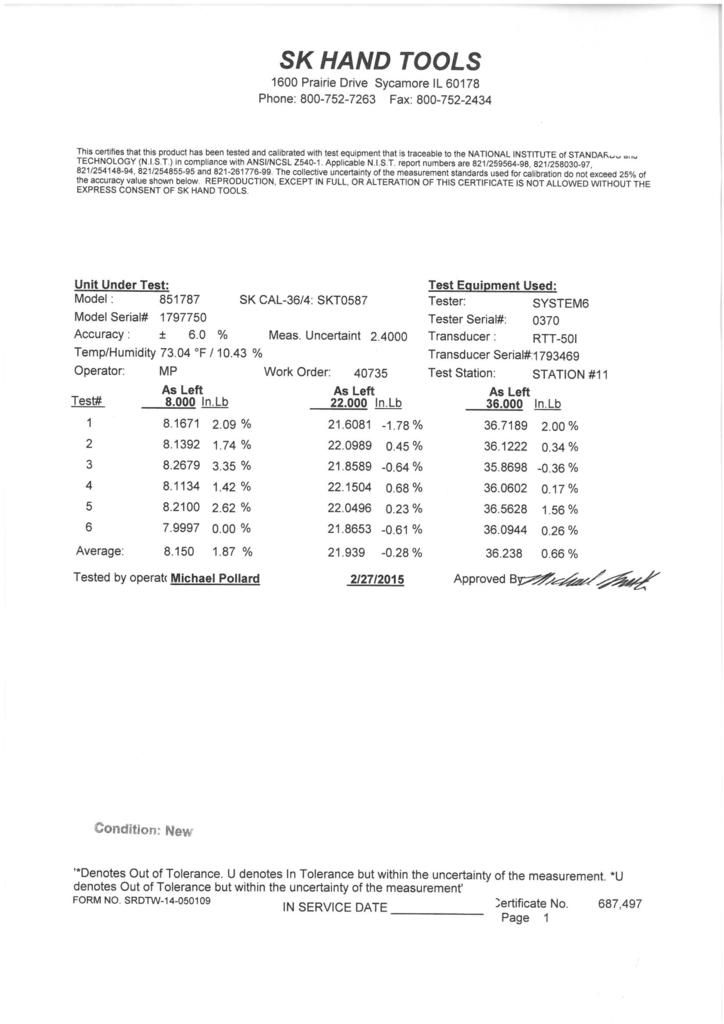

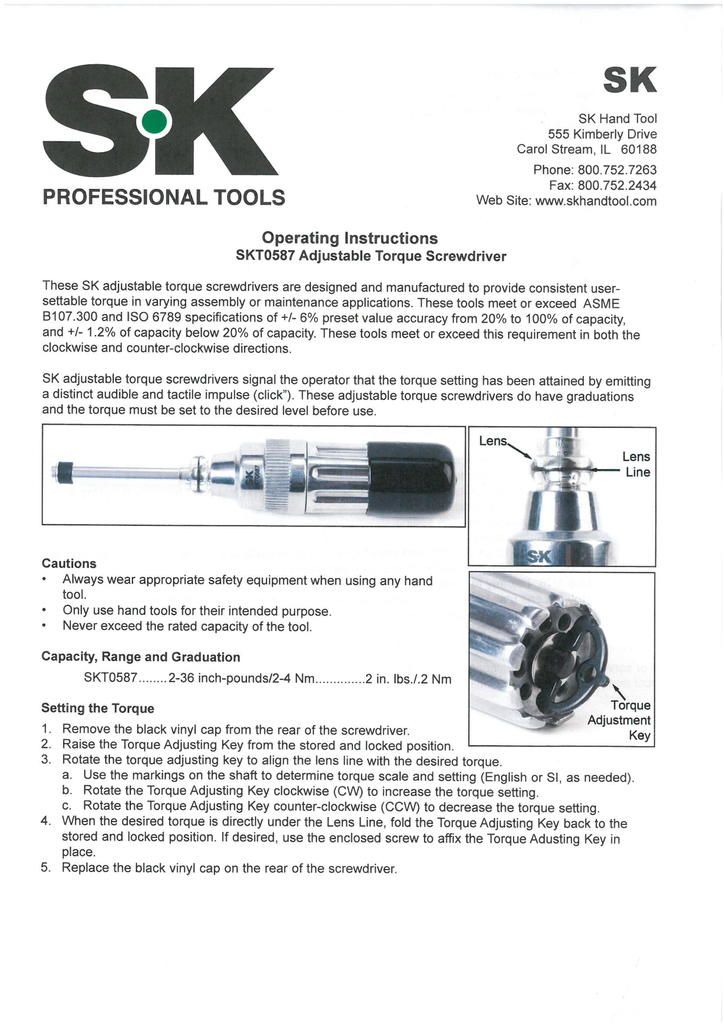

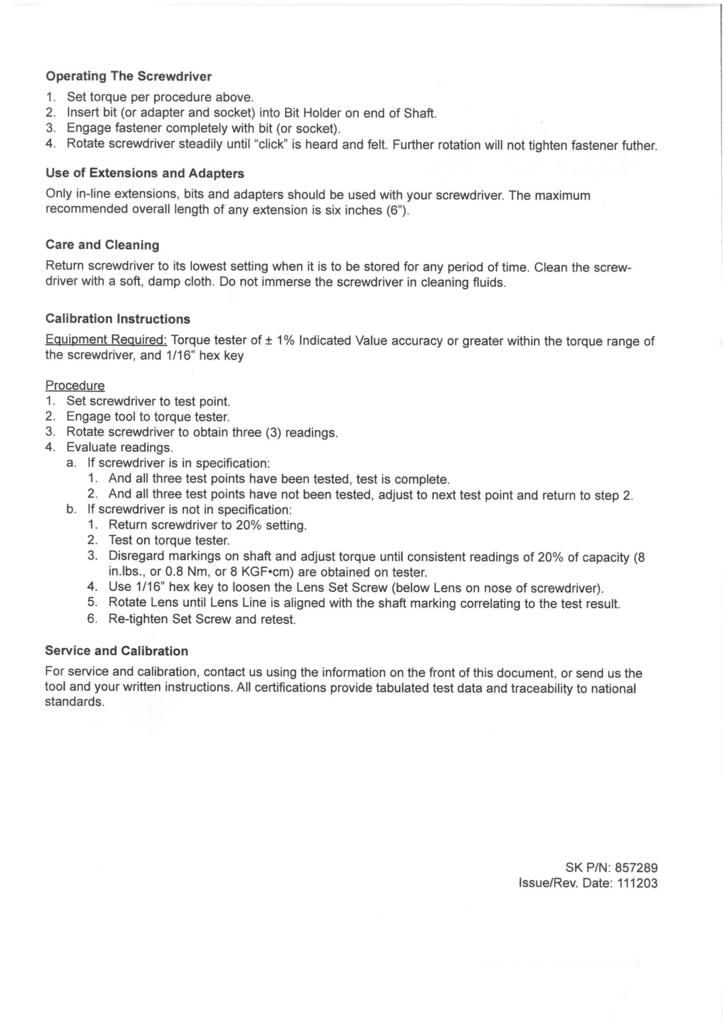

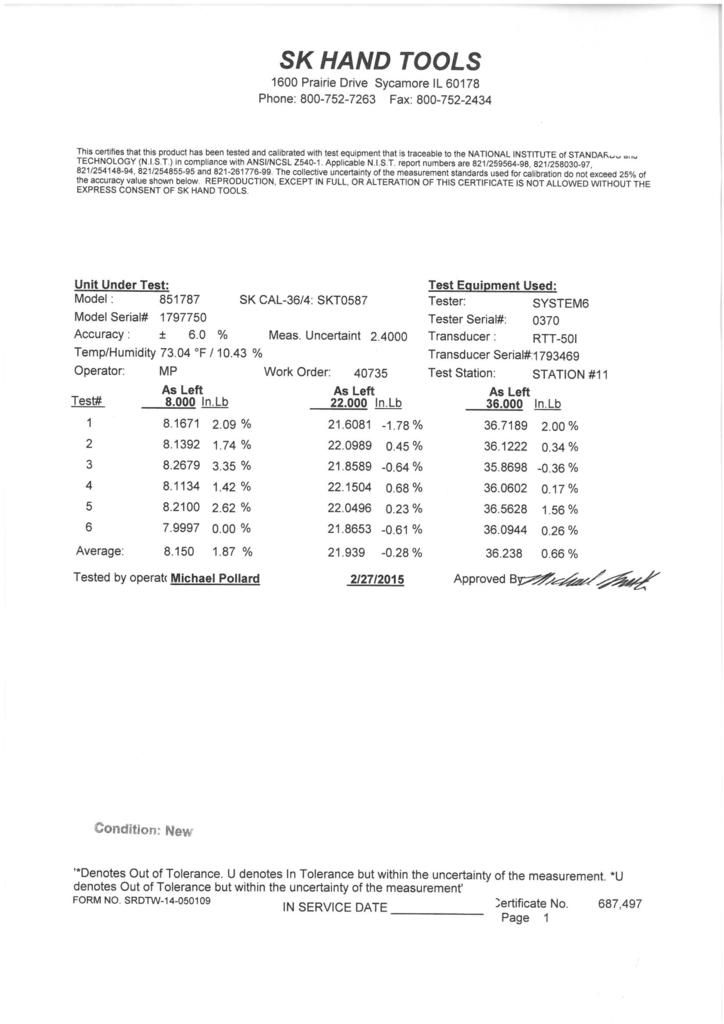

SK/SR driver

A comment on the torque driver availability. There seems to be a good offer on amaz/us for something that looks much like the Sturtevant. It comes calibrated and I just received one here.

BR Klaus

BR Klaus

Re: Klimax DS torque recommendations

Yes, that is the same driver. It is most likely made for SK tools OEM by Sturtevant Richmont. There was a time when Sears sold the CAL 36/4 as a Craftsman tool even though it said Sturtevant Richmont on the tool itself.

You can also get the same tool in a kit with a plastic case and a couple dozen bits for under $20.00 more from Amazon US as well.

You can also get the same tool in a kit with a plastic case and a couple dozen bits for under $20.00 more from Amazon US as well.

The LP12 Whisperer

Manufacturer, Distributor, Retailer and above all lover of music.

Manufacturer, Distributor, Retailer and above all lover of music.

-

Spannko

- Very active member

- Posts: 2297

- Joined: 2008-01-24 21:46

- Location: North East of The Black Country, UK

Re: Klimax DS torque recommendations

I've got one of these.

http://www.amazon.co.uk/gp/product/B00N ... 1_1&sr=8-1

It was only £40 and has an accuracy of 1%.

http://www.amazon.co.uk/gp/product/B00N ... 1_1&sr=8-1

It was only £40 and has an accuracy of 1%.

Re: Klimax DS torque recommendations

Accuracy is not the issue, precision in the torque setting is. The latter is what makes the Sturtevant Richmont unique.Spannko wrote:I've got one of these.

http://www.amazon.co.uk/gp/product/B00N ... 1_1&sr=8-1

It was only £40 and has an accuracy of 1%.

Which is the smallest step you can make with this tool?

Re: Klimax DS torque recommendations

The mechanical principle of the Sealey is different:

If the target torque is reached,the buzzer will sound, the LED indicator will light and the handle will vibrate for approx. 2 seconds.

If the target torque is reached,the buzzer will sound, the LED indicator will light and the handle will vibrate for approx. 2 seconds.

Re: Klimax DS torque recommendations

I see. That doesn't sound good. I have tried using the S R tool in a similar way: Rotating it until it starts slipping, before it clicks. This doesn't become precise, perhaps partly due to the frictions involved in the fastener. Much better is to let it click 5-6 times. I have also found that there is a slight variation in torque between the clicks, so letting it click multiple times makes sure the highest value is where it ends up.k_numigl wrote:The mechanical principle of the Sealey is different:

If the target torque is reached,the buzzer will sound, the LED indicator will light and the handle will vibrate for approx. 2 seconds.

I'd say that in practice, this way of using the S R tool makes the accuracy higher than any other torque tool I've tried.

-

Spannko

- Very active member

- Posts: 2297

- Joined: 2008-01-24 21:46

- Location: North East of The Black Country, UK

Re: Klimax DS torque recommendations

The smallest step is 0.01 Nmlejonklou wrote:Accuracy is not the issue, precision in the torque setting is. The latter is what makes the Sturtevant Richmont unique.Spannko wrote:I've got one of these.

http://www.amazon.co.uk/gp/product/B00N ... 1_1&sr=8-1

It was only £40 and has an accuracy of 1%.

Which is the smallest step you can make with this tool?

It comes with a certificate of calibration. When set at 1 Nm, mine produced readings of 0.99, 0.99, 1.00, 1.00, 1.01 Nm clockwise, and -0.99, -0.99, -1.00, -1.01, -1.02 Nm anti-clockwise.

If you want to try it out, I can send it to you.

Re: Klimax DS torque recommendations

That sounds pretty good. Thanks for the offer!Spannko wrote:The smallest step is 0.01 Nm

But: If it doesn't slip when you've reached the set torque, but only makes a sound, how can you be accurate? I mean; suppose you want to set a fastener to 0.97 Nm. You tighten until it beeps, but nothing stops you from going to far, does it? At which torque does the fastener end up in practice?

Re: Klimax DS torque recommendations

Seems it does not slip when target torque is reached.

Great price! Any good?

This may help

http://www.sitebox.ltd.uk/docs/sealey/pdf/STS103.pdf

Donuk, sunny downtown York

Great price! Any good?

This may help

http://www.sitebox.ltd.uk/docs/sealey/pdf/STS103.pdf

Donuk, sunny downtown York

-

Spannko

- Very active member

- Posts: 2297

- Joined: 2008-01-24 21:46

- Location: North East of The Black Country, UK

Re: Klimax DS torque recommendations

It also has a digital readout displaying steps of 0.01 Nm, so you can watch the torque approach the desired setting. It's a bit like putting 100 litres of petrol in a car - with practice, you can get it bang on.lejonklou wrote:That sounds pretty good. Thanks for the offer!Spannko wrote:The smallest step is 0.01 Nm

But: If it doesn't slip when you've reached the set torque, but only makes a sound, how can you be accurate? I mean; suppose you want to set a fastener to 0.97 Nm. You tighten until it beeps, but nothing stops you from going to far, does it? At which torque does the fastener end up in practice?

However, I'm really struggling to understand how can be of any practical help, other than it's just a bit more "accurate" (I don't think the word is appropriate tbh) than hand tightening by an experienced operative.

From what I understand, torque is a poor indicator of fixture tightness, or inter-surface pressure. The same torque values can have have about a 25% difference in inter-surface pressure. Hand tightening can achieve errors down to about 35%.

The main problem appears to be variable friction levels between the moving surfaces, not the equipment used to measure the torque.

The "angle of turn" method can bring the errors down to about 15%, so may be worth investigating. It's at least as twice as "accurate" as using "feel".

It's possible to get the accuracy down to about 10% by using load indicating washers, but I've not seen anything which works at such low values of pressure and I'm sure they would have an effect on the sound too.

Using strain gauges and ultrasonics can get the accuracy down to about 1%

I looked into the subject of torquing because the Sealey torque driver allows one to measure un-tightening torque in addition to tightening torque. I noticed that the un-tightening torque was quite a bit lower than the tightening torque (about 50-70%) and very variable. I thought that I had a problem with my technique, but apparently this is absolutely normal.

I'll continue to use my torque driver, in the knowledge that, for our application, it's just a bit better than tightening by hand.

Re: Klimax DS torque recommendations

Yes, I noticed long ago that un-tightening is very variable and usually far lower than the tightening torque.

Your tool does seem interesting, but I wonder how close to the peak in performance one can get with it in practice.

As I mentioned before, I find that the repeated clicking of the CAL 36/4 is necessary for arriving at the optimal torque. I suspect that the vibrations and repeated peaks of torque is what makes it so accurate. Because in practice it is VERY accurate - far from the big numbers you're mentioning. This is easily confirmed by listening. You can go back and forth between two torques that are very close and get the same musical differences every time.

Your tool does seem interesting, but I wonder how close to the peak in performance one can get with it in practice.

As I mentioned before, I find that the repeated clicking of the CAL 36/4 is necessary for arriving at the optimal torque. I suspect that the vibrations and repeated peaks of torque is what makes it so accurate. Because in practice it is VERY accurate - far from the big numbers you're mentioning. This is easily confirmed by listening. You can go back and forth between two torques that are very close and get the same musical differences every time.

Re: Klimax DS torque recommendations

I wonder if one of you learned people could explain the physics of why critical torque settings affect the sound of HiFi equipment. I can understand that if something is excessively loose it will rattle, and maybe have microphonic consequences. But I cannot understand why it is necessary to make the very fine adjustments being discussed here.

Like so many issues in HiFi. I don't doubt your findings, but I would like to better understand them.

Thanks

Donuk.

Like so many issues in HiFi. I don't doubt your findings, but I would like to better understand them.

Thanks

Donuk.

Re: Klimax DS torque recommendations

I don't know, Don. But I have found that the better the system sounds, the easier it becomes to hear differences related to microphony.

For instance, there is a massive difference between spruce and birch in a shelf of a Harmoni rack. And between 2 and 3 mm washers clamping that shelf. And between how tight you clamp them.

More and more, it resembles the building and tuning of a musical instrument.

For instance, there is a massive difference between spruce and birch in a shelf of a Harmoni rack. And between 2 and 3 mm washers clamping that shelf. And between how tight you clamp them.

More and more, it resembles the building and tuning of a musical instrument.

-

Spannko

- Very active member

- Posts: 2297

- Joined: 2008-01-24 21:46

- Location: North East of The Black Country, UK

Re: Klimax DS torque recommendations

I totally agree.lejonklou wrote:I don't know, Don. But I have found that the better the system sounds, the easier it becomes to hear differences related to microphony.

For instance, there is a massive difference between spruce and birch in a shelf of a Harmoni rack. And between 2 and 3 mm washers clamping that shelf. And between how tight you clamp them.

More and more, it resembles the building and tuning of a musical instrument.

-

Spannko

- Very active member

- Posts: 2297

- Joined: 2008-01-24 21:46

- Location: North East of The Black Country, UK

Re: Klimax DS torque recommendations

I wondered about this too.lejonklou wrote:Yes, I noticed long ago that un-tightening is very variable and usually far lower than the tightening torque.

Your tool does seem interesting, but I wonder how close to the peak in performance one can get with it in practice.

As I mentioned before, I find that the repeated clicking of the CAL 36/4 is necessary for arriving at the optimal torque. I suspect that the vibrations and repeated peaks of torque is what makes it so accurate. Because in practice it is VERY accurate - far from the big numbers you're mentioning. This is easily confirmed by listening. You can go back and forth between two torques that are very close and get the same musical differences every time.

Then I discovered that stiction (static friction) is always higher than friction. So if the mating surfaces are moving relative to one another, the torque required to overcome the friction is being measured. That's the easy bit! If the mating surfaces are stationary......I'm not sure what's being measured - I think it depends on the tool being used.

The Sealey can't measure the force required to overcome stiction. One has to gradually increase the torque by hand until the desired torque is reached, then stop. There is no way of checking it again because to do so would mean gradually increasing the torque by hand until the desired torque is reached again. But, because the desired torque will now be below the stiction torque, the bolt wouldn't move so the exercise would be pointless, or if the bolt moves, the required torque will be exceeded.

I think there is a fundamental difference between the Sealey (which uses a strain gauge) and the SR (which uses a ball which jumps out of a cup when the set torque is reached). The SR can be used to set the torque required to overcome friction, and also used to measure "something" when the bolt is stationary. I'm thinking that all the SR can really indicate in this instance is that the torque required to overcome the stiction is greater than the torque required to force the ball out of the cup. This won't be the same as the torque required to overcome the friction (it'll be higher - it could be 1% higher, it could be 10% higher, it could be 100% higher - there's no way of knowing). However, the calibration certificates suggest the error will be about +/- 0% to +/- 3.35% for the SR and +/- 1.0% for the Sealey.

Differences in friction and stiction between mating surfaces of the same components? Let's not go there - it gets even worse !